Who is a Garment Technologist?

To secure a job in the fashion or retail industry as a garment technologist, applicants will have in-depth technical knowledge of the design, patterns, and fabrics of garments, as well as a good understanding of the manufacturing processes in a fashion and retail environment. Garment technologists also value detail and the ability to work in a fast-paced environment. As a clothing technician, you are responsible for the fit and sealing of clothing within the fashion company, be it women’s clothing, men’s clothing, children’s clothing, fashion accessories, or shoes.

To get a job in fashion as a clothing technician, you need a unique degree in fashion engineering. You start out as a clothing engineer, then move on to become a junior clothing technologist and then a clothing technician. From there, you can switch to a technical manager or technical manager in a fashion / retail company.

In addition to being a stylist, there are many less popular websites for making clothes before they hit the shelves. The apparel technologist is one of those key roles in ensuring that the production of the end product goes smoothly. As fashion companies continue to outsource production to other countries, there will always be a need for apparel technologists. As the communication between the brand and the factory, the apparel technician is responsible for ensuring that the vision of the product is aligned and as intended. If you are a practical and practical person, becoming a fashion technician might be your job.

How to become a garment technologist?

One way to gain the experience of a clothing technologist is to start as a model maker with a supplier. Because suppliers usually have machines, they can understand the design and see for themselves how garments are made and assembled. It is also helpful to learn how to use apparel technology to develop the modeling skills required to become a professional apparel technologist.

What to study for becoming a garment technologist

It is important for a garment technologist to study fashion design and development at an art school and gain experience in cutting patterns. You need to be aware of body types, fabric expressions, construction, and basic math to get the job done right.

International brand versus startups

Global companies typically invest in young talent and may offer many free courses that are great for young talent. However, progress can be slow. If you’re the type who wants to get ahead faster, apply for a job with a smaller company. As a team member at the start, your contribution can be more thoughtful and you can also apply new ideas and ways of working.

What it takes to be successful in this field

To be successful, you need to be highly motivated and able to see the big picture. You shouldn’t work near you, but always be ready to learn. For example, even if you start out as a part-time model maker with a supplier, showing leads and making connections, you may be a clothing technologist with an international brand from one of the customer leads you to build.

The role of a garment technologist

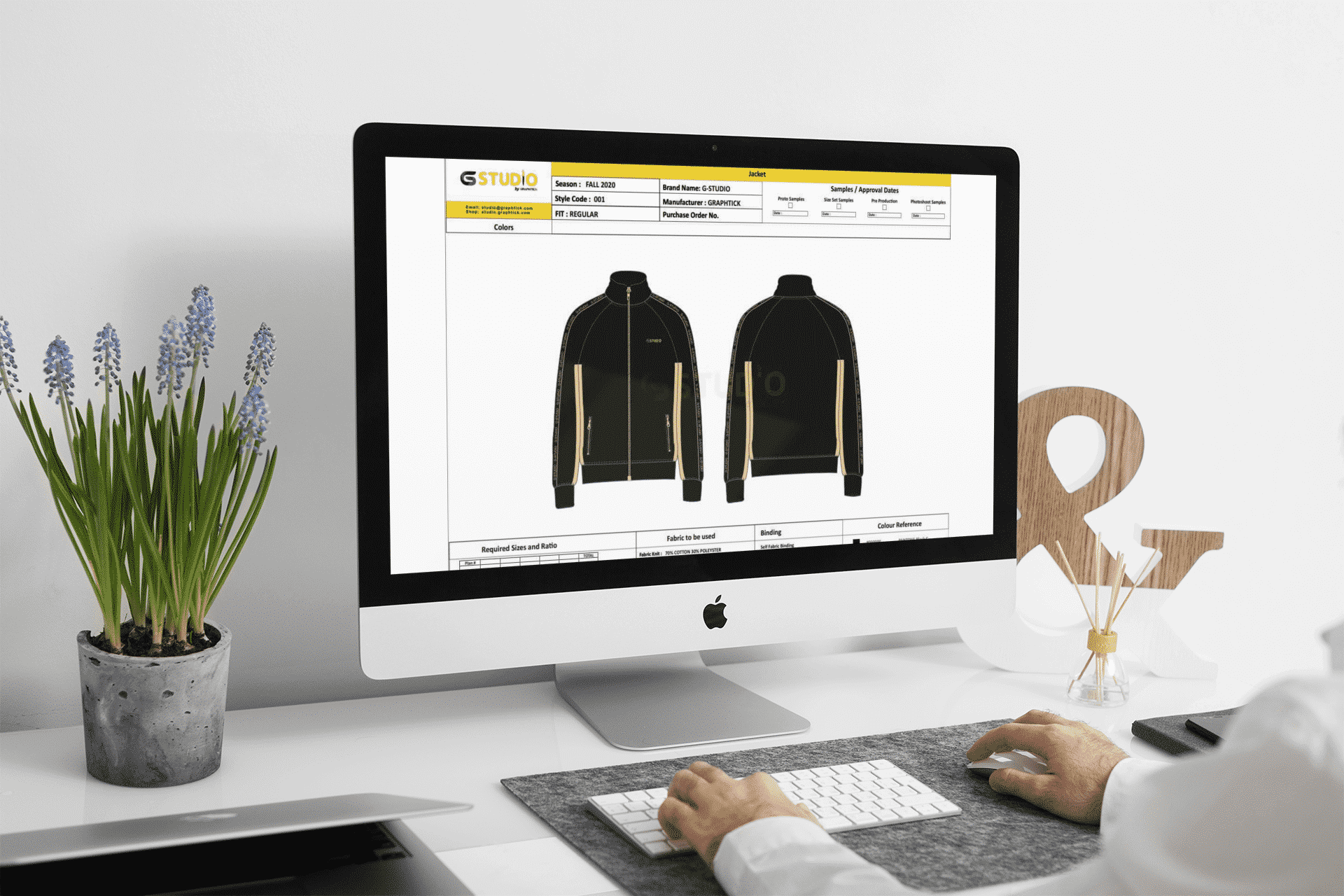

A garment technologist is responsible for the correct fit and execution of a garment. Working closely with the design team and the factory, a clothing technologist oversees the measurements and construction of the garments to enable prototype production. An important role is played by the garment technologist in direct contact with factories around the world to provide feedback. Here are some examples of the jobs and skills fashion companies look for in a clothing technologist.

Main tasks and skills required for garment technologists:

- He works closely with the purchasing, design, merchandising, and delivery base.

- Assess the safety risk of the products and analyze the test reports.

- Evaluate the quality of the materials and review the final product.

- Learn wear tests on appropriate days to ensure the product is competitive and ahead of market trends.

- Experience in cutting and classifying patterns is required.

- Establishing and maintaining relationships with suppliers, procurement regions, and technical laboratories.

- Good understanding of manufacturing capabilities and the ability to conduct factory production evaluations

- Knowledge of Product Lifecycle Management (PLM) and Adobe systems is desirable.

How are:

- You will help to change the models into clothes that people want to buy and wear.

- You can select and source different fabrics that a designer can use. You explain to your designer how clothes can be made in a more efficient way.

- You have expertise in the following areas:

- Production methods such as sewing and cutting patterns

- Different fabrics and their properties

- Clothing production process

- Fashion and retail

- The design and purchasing teams rely on your experience at every stage of product development, from design to testing and then to making clothes for the stores.

You would like:

- Suggest design changes

- Advice on suitable substances

- Make sure the clothes are made to the highest standard

- Ensure that garments can be made within budget

- Supervision of tests on materials and equipment of first samples

- Answer product questions

- Analyze product returns and errors

- You would work closely with other employees such as designers, pattern makers, and selectors as well as buyers.

- Clothing technologists oversee all stages of garment manufacturing, from design to manufacturing. You are involved in choosing the right fabric and ensuring that production falls within budget. You work closely with designers, pattern makers, and buyers.

The work

You could be:

- Work with designers to ensure that the design adheres to manufacturing methods

- Find, select and purchase suitable fabrics and accessories

- Garment size and production planning

- Work with pattern selectors to size pre-made garments and advice tailors and machinists on pattern making

- Review and approve sample garments and make any necessary changes, including troubleshooting

- Ensure that garments can be made within budget

- Visit garment factories to review the process and advise staff

- Ensure garments are delivered on time and in good condition and customer satisfaction is guaranteed

- Establish good collaboration with suppliers.

Read more at studio.graphtick.com

0 comments