What is BOM in your Fashion Technical Pack?

A Bill of Materials (BOM) is one of the most important parts of your technical pack. It helps you not to lose a single thread, button, zipper, or small detail in the creation of your garment. It is also an important tool for assessing quality and determining the cost and price of your products.

Read on for a full BOM update – what it is, why it’s important, and some examples.

What is a Bill of Materials (BOM) in Technical Pack?

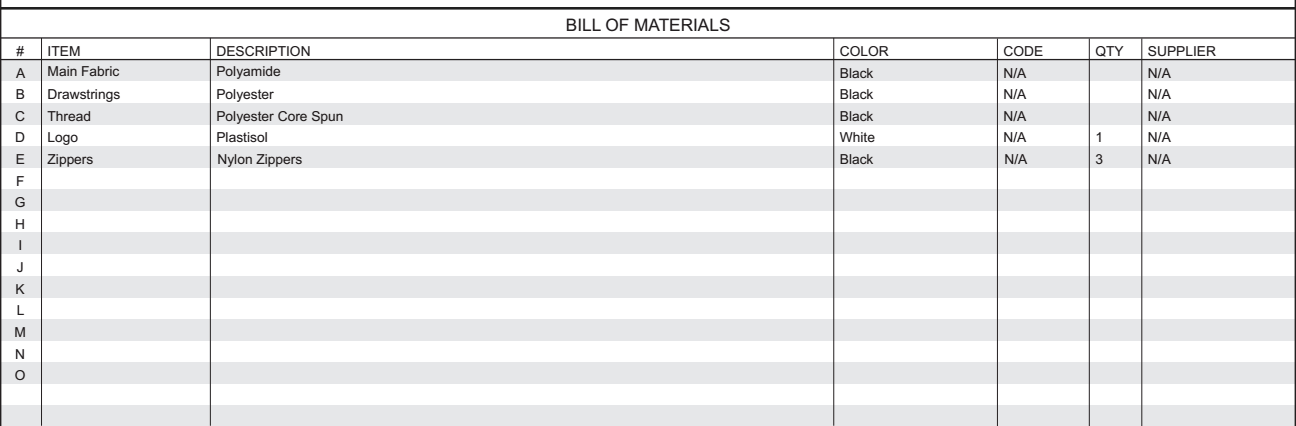

It is a list of components of your product with their costs and quantities.

There is a parts list specific to each color. That is to say, if you have three 3 color options, you will need a parts list for each color. Think of it as a recipe and a shopping list for creating fashion products. It is a core document that uses all roles in the supply chain: designers, buyers, buyers, and sellers. So make sure all tech packs are accompanied by a 100% complete and accurate BOM. You also use it to communicate with your manufacturing partner. This helps you and your factory stay on the same page during production. Manufacturers work with many different brands and customers. You have many fabrics, finishes, and details in mind. A comprehensive, easy-to-read parts list will give your factory a better feel for the time it takes to cut and sew. This also makes it easier to determine the true cost of your product and its price fluctuations.

Here are 5 reasons Bill of materials (BOMs) in Technical Pack is necessary

1- It is your personalized shopping list

Your bill of materials lists all the raw materials and quantities needed to create your fashion product. Materials cannot be sourced without them.

2 – Best costs and prices

Since each material is listed according to its respective quantities and current prices, the BOM indicates how much the product will cost today below current market prices.

From there, you can easily calculate your potential profit margins and develop a suitable pricing strategy for your product.

3 – There will be no missing components in your factory

You can make your BOM more useful by listing the materials in the correct order. This creates a potential source of failure in your factory. Imagine an engine in a car factory for seconds. Without all the components listed in the correct order, it will never work! When listing materials for clothing items, unlike a machine, you have more flexibility in the order of things.

4 – Creating production standards through BOM

A garment has to go through several steps from the beginning to the final sequence. The BOM will help you introduce this process to your factory and understand how raw materials are converted into the final product.

Once defined, the BOM can be used as part of the standard manufacturing process to ensure quality and consistency for each batch.

5 – Help the whole supply chain to work as a unit

A parts list naturally helps each department work together. To create an accurate parts list, you need input from design, supply, manufacturer, and sales.

Benefits of using G Studio services to create and manage BOMs in Technical Pack

- Perfect Formatting – It’s as great as it sounds. With one click, the parts list is formatted for you and ready to print.

- Version control: All versions of the BOM are saved in the cloud and provided with a time stamp. This ensures that everything is organized in one place and not spread between emails and shared drives.

- Easy sharing: Control access to technical parts lists and technical packs. Share them with staff and producers. You can even share different versions with a link for read-only format.

- Unlimited reusable: the content bill consists of cards, each with design details. You can save all parts of the bill of material BOM in other tech packs and then reuse them.

Read more at studio.graphtick.com

0 comments