Apparel Tech Packs: Your Essential 2025-2026 Guide

As the fashion industry evolves, tech packs have become essential for apparel design and production.

A tech pack is a detailed document that outlines everything needed to create a clothing item, ensuring clear communication between designers and manufacturers.

In 2024-2025, understanding Apparel Tech Packs can streamline your process and reduce costly errors.

It includes technical drawings, fabric specifications, measurements, and production timelines.

The importance of tech packs continues to grow as brands seek efficiency and consistency.

Adopting best practices for creating Apparel Tech Packs can help you stay competitive in today’s fast-paced market.

This post will guide you through the key components and trends shaping tech packs in the coming years.

Tech Packs Overview

A tech pack is an essential tool in apparel design. It serves as a detailed guide for manufacturers to create your clothing.

Key components of a tech pack include:

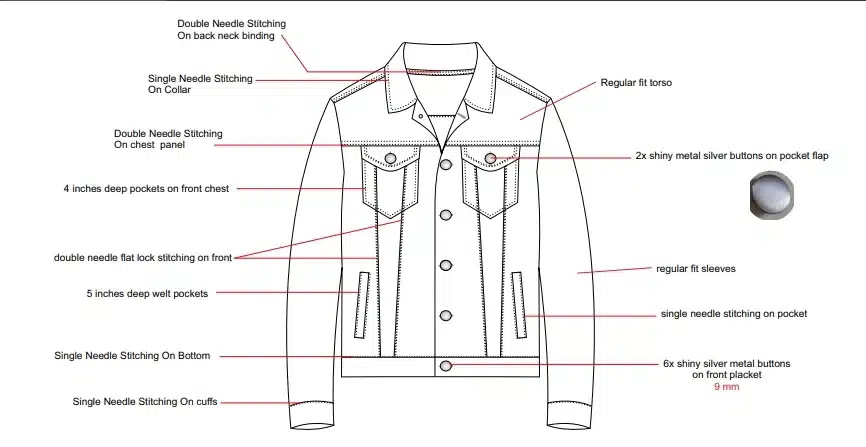

- Technical Drawings: Clear images showing design details.

- Material Specifications: Descriptions of fabrics and materials used.

- Size and Fit Charts: Measurements to ensure the correct sizing.

- Construction Details: Instructions on how the garment should be made.

- Label Information: Details about care labels, tags, and branding.

Using tech packs can streamline the production process. They help reduce errors and miscommunication between you and the manufacturer.

You can create a tech pack using templates or design software. Many companies offer online tools that make it easier to build your pack.

When your tech pack is complete, it should be easy to understand. This clarity helps ensure that the final product matches your vision. Proper documentation also helps in meeting deadlines and managing costs.

Significance of Apparel Tech Packs Design

Tech packs play a vital role in apparel design. They serve as a detailed guide between designers and manufacturers, helping ensure that products meet expectations. The focus of this section is to explore their importance in communication, quality control, and cost estimation.

Communication with Manufacturers of Apparel Tech Packs

Clear communication is crucial in Tech packs in apparel design.

Tech packs provide all the necessary details that manufacturers need. This includes materials, colors, sizes, and construction techniques.

By including accurate specifications, you reduce the risk of misunderstandings. This helps prevent costly mistakes in production. You can also include sketches and diagrams that visually explain your ideas.

When all information is in one place, it streamlines the process. Manufacturers can reference the tech pack throughout production. This leads to smoother collaboration and faster turnaround times.

Check the Tech pack example : Tech Pack Template free

Quality Control for Apparel Tech Packs

Quality control is essential to creating a successful apparel line. Apparel Tech Packs set quality standards that must be met. By specifying fabric types, stitching methods, and fit details, you make sure the final product matches your vision.

You can outline testing requirements, such as washability or durability. This ensures that the manufacturer follows guidelines you set. Regular checks against the tech pack can catch issues early in production, saving you time and money.

Having a well-structured tech pack helps maintain consistent quality. This builds a strong brand reputation and increases customer satisfaction.

Cost Estimation for Apparel Tech Packs

Understanding costs is important for any apparel project. Tech packs aid in accurate cost estimation by providing clear details about materials and labor. With all specifications laid out, manufacturers can give precise quotes.

You can list materials and their associated costs in the tech pack. This allows you to evaluate different options and find the best fit for your budget.

By including multiple vendors for materials, you can compare prices easily. Solid tech packs help you stay within budget while creating high-quality apparel.

Creating Effective Apparel Tech Packs

Creating a tech pack involves careful planning and the use of the right tools. Your tech pack should communicate all necessary information clearly to enhance the production process.

Software Tools for Apparel Tech Packs Creation

Using the right software can simplify your tech pack creation. Here are some popular tools you can consider:

- Adobe Illustrator: Great for creating detailed sketches and technical drawings. It’s widely used in the fashion industry.

- CLO 3D: This software helps you create 3D garment simulations. You can visualize designs before production.

- TUKAcad: This is useful for pattern making and grading. It simplifies the process of digitizing patterns.

Choosing a tool that fits your needs can save time and help avoid errors.

Best Practices in Compilation

When compiling your Apparel Tech Packs, focus on clarity and detail. Here are some key practices:

- Include Clear Specifications: Always outline measurements, materials, and colors in detail. Use charts or tables for easy reference.

- Add Technical Drawings: Provide front, back, and side views of the garment. Label all parts, like seams and trims.

- Use Visual References: Include images or samples of fabrics and colors. This helps factories understand your vision.

- Organize Information: Arrange your tech pack in a logical order. Sections should include an introduction, specifications, materials, and production timelines.

- Review and Revise: Before sending out your tech pack, check for any missing information or errors. A thorough review helps prevent confusion.

Evolving Standards in Apparel Tech Packs Development

Tech packs are more important than ever in apparel production. They serve as detailed guides for manufacturers. This clarity ensures that your designs are made accurately.

New standards are emerging in this field. These include digital formats that improve communication. Many companies now use cloud-based systems. This allows for easier updates and sharing with teams.

Key Elements in Modern Apparel Tech Packs:

- Technical Drawings: Clear illustrations of your designs.

- Materials List: Details on fabrics and trims.

- Sizing Specifications: Exact measurements for each size.

- Color Codes: Accurate color references to avoid confusion.

You can also incorporate sustainability standards. Many brands are focusing on eco-friendly materials. Including this information in your tech pack helps align with customer values.

Collaboration has become a crucial part of tech pack development. You can work more closely with your suppliers. This ensures that any issues are addressed early in the process.

Investing in technology is key. Many software tools are designed to simplify tech pack creation. These can enhance productivity and ensure standards are met.

In summary, evolving standards in tech pack development reflect changes in technology, sustainability, and collaboration. Adapting to these trends can lead to better outcomes for your apparel line.

The Role of Technology in Apparel Tech Packs Automation

Technology plays a crucial role in automating tech packs, making the design and production process more efficient. Automation reduces errors and speeds up production.

Key Technologies Involved:

- Software Solutions: Programs like Adobe Illustrator and CAD systems help create accurate designs quickly.

- Cloud-Based Platforms: These allow team members to access tech packs from anywhere, promoting collaboration.

- Integration with Manufacturing: Technology connects your tech pack directly with manufacturers. This streamlines communication and updates.

Benefits of Automation:

- Time Savings: Automation minimizes manual tasks, letting you focus on creative work.

- Consistency: Automated tools ensure that measurements and specifications remain uniform across all designs.

- Feedback Loops: Technology can help gather feedback quickly, allowing for faster revisions.

Adopting technology in creating tech packs simplifies the entire process. It allows you to produce detailed documents that guide production accurately.

As the industry evolves, technology continues to improve how tech packs are created and managed. Embracing these advancements can lead to better products and satisfied customers.

Environmental and Ethical Considerations Apparel Tech Packs

You should focus on sustainability and ethics when creating tech packs in apparel. These areas are increasingly important to consumers, brands, and manufacturers. Sustainable materials and ethical manufacturing processes can greatly impact your brand’s reputation and success.

Sustainable Materials Sourcing

Choosing sustainable materials is critical for reducing environmental impact. Look for fabrics made from organic cotton, recycled polyester, or bamboo. These materials often use less water, energy, and harmful chemicals during production.

You can also consider:

- Certifications: Look for materials certified by organizations like GOTS (Global Organic Textile Standard) or OEKO-TEX.

- Local Sourcing: Reducing transportation miles helps lower your carbon footprint.

- Eco-Friendly Dyes: Opt for dyes that have less impact on the environment.

By prioritizing these materials, you can make a positive contribution to the planet while appealing to eco-conscious consumers.

Ethical Manufacturing Processes Apparel Tech Packs

Ethical manufacturing goes beyond simple compliance with labor laws. It involves ensuring fair wages, safe working conditions, and respect for workers’ rights. To achieve this, partner with manufacturers who share these values.

Important practices to consider include:

- Transparency: Make sure your supply chain is clear and open. This builds trust with consumers.

- Worker Welfare: Look for factories that provide healthcare and reasonable work hours.

- Equal Opportunity: Ensure that all workers are treated fairly, regardless of gender or background.

Focusing on ethical manufacturing not only enhances your brand image but also helps create a better industry overall.

Global Compliance and Regulations of Apparel Tech Packs

In the apparel industry, understanding global compliance and regulations is crucial. Different countries have varying laws regarding textiles, labor, and environmental standards.

Key Areas of Compliance:

- Safety Standards: Products must meet safety regulations to avoid risks to consumers. This includes flammability and harmful substance testing.

- Environmental Regulations: Manufacturers must comply with laws aimed at reducing pollution and waste. This includes restrictions on harmful chemicals and proper waste management.

- Labor Laws: Fair labor practices are essential. You need to follow laws related to worker rights, wages, and working conditions.

Important Regulations to Know:

- REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) – A European Union regulation that affects materials used in textiles.

- OSHA (Occupational Safety and Health Administration) – In the U.S., this ensures safe working conditions in manufacture.

- Consumer Product Safety Improvement Act (CPSIA) – This law mandates safety testing for children’s apparel.

Tips for Staying Compliant:

- Regularly check regulations in your target markets.

- Work with legal experts or consultants who specialize in apparel laws.

- Keep records of compliance efforts to avoid fines or penalties.

Understanding these regulations helps protect your brand and consumers.

Challenges and Solutions in Apparel Tech PacksCreation

Creating tech packs can be difficult. Here are some common challenges you may face and possible solutions.

1. Lack of Detail

many tech packs are incomplete, leading to misunderstandings.

Solution: Include clear descriptions, sketches, and materials to avoid confusion.

2. Communication Gaps and miscommunication between designers and manufacturers can cause errors.

Solution: Use detailed notes and visuals to ensure everyone understands the requirements.

3. Time Constraints you might rush the tech pack process, which can lead to mistakes.

Solution: Set realistic timelines and incorporate extra review periods to catch errors.

4. Rapid Fashion Changes The fast-paced fashion industry can lead to outdated Apparel Tech Packs.

Solution: Regularly update your tech packs to reflect current trends and materials.

5. Software Limitations not all software allows for easy editing or sharing of tech packs.

Solution: Choose user-friendly tools that support collaboration and updates.

6. Quality Control Issues

Products may not meet quality standards due to lack of clear guidelines.

Solution: Define quality control measures in your tech pack, specifying tests and criteria.

By addressing these challenges with practical solutions, you can create effective tech packs that improve communication and production quality.

The Future of Tech Packs in Apparel Industry

Tech packs are becoming essential in the apparel industry as brands aim for speed and accuracy. You will see more companies using digital tools to create and manage these packs. This trend will help in reducing errors and improving communication.

Key features expected in future tech packs include:

- Digital Collaboration: Designers and manufacturers can work together in real time, allowing for quick updates and feedback.

- 3D Design: You will see 3D models being used more frequently, making it easier to visualize the final product.

- Sustainability Focus: Tech packs will include information on sustainable materials and eco-friendly practices.

As technology advances, artificial intelligence may play a role in generating tech packs. This could streamline the process and ensure that you get accurate specifications.

Additionally, more companies will adopt modular tech packs. This allows for easier modifications based on market trends or consumer preferences. You can expect tech packs to become more tailored to specific target markets.

The use of QR codes in tech packs will also increase. These codes can connect consumers to information about the product, including sourcing and care instructions.

In the coming years, you can count on tech packs to not only support design but also enhance the overall customer experience.

0 comments